Grp lamination is a process used to create laminated sheets of fiberglass reinforced plastic (FRP). It is a very useful process for creating strong and lightweight structures, such as boat hulls, parts for cars and trucks, and other items.

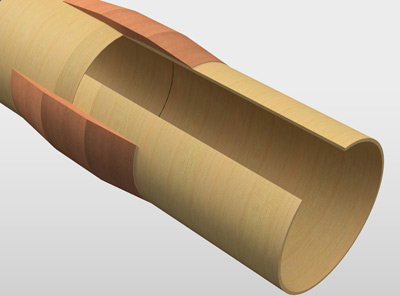

The process begins by laying down a layer of fiberglass cloth on a flat surface. This layer is then bonded to the surface with a resin, such as polyester or epoxy. Once this layer has cured, a second layer of fiberglass cloth is laid over the resin. This process is repeated, with each layer having a different orientation of the fiberglass strands.

Once the desired number of layers have been laid down, the entire laminate is placed into an oven and heated. This heat causes the resin to cure and bond the fiberglass layers together. The result is a single sheet of fiberglass reinforced plastic (FRP).

Grp lamination is a very popular process for creating strong, lightweight structures. It is often used in the production of boats, ships, and car and truck parts. It is also used to create lightweight and strong structures for buildings and other architectural applications.

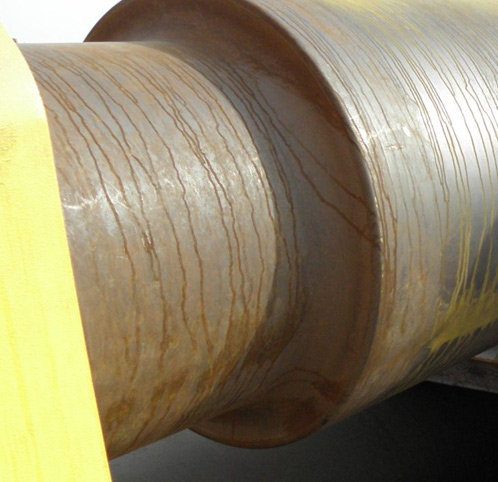

GRP (Glass-Reinforced Plastic) water tank lamination is a specialized process used to protect and reinforce the structural integrity of a water tank. This process involves the application of a layer of resin and glass fibers to the structural elements of the tank to create a stronger, more durable, and more watertight container. The lamination process begins with the preparation of the tank. This includes cleaning and degreasing the surface to ensure that the lamination is applied correctly. Once the surface is ready, a layer of resin is spread over the area to be laminated. The resin is then catalyzed to harden the material and create a strong bond between the resin and the tank.

Our knowledgeable staff will conduct research as soon as we obtain a laminating requirement in order to prepare the project's methodology.

Following the plan, our committed employees will begin carrying it out using their expertise and passion.

Our support staff will follow up with customers on a regular basis once the job is finished to make sure the quality is maintained.